Many people associate product standards with safety, but standardization also has a lot to do with a product’s cost. Rittal created a market breakthrough with the idea of standardizing enclosures for electrical devices. By using models with set dimensions, produced cost-effectively in large batches, Rittal is able to offer price and delivery benefits.

Rittal North America LLC

Recent Posts

Why Standards Are Important to an Enclosure’s Value

[fa icon="calendar'] Aug 27, 2015 1:00:52 PM / by Rittal North America LLC posted in Industrial Automation

Thermal Management and Rittal TopTherm Units

[fa icon="calendar'] Jul 24, 2015 2:02:00 PM / by Rittal North America LLC posted in Industrial Automation

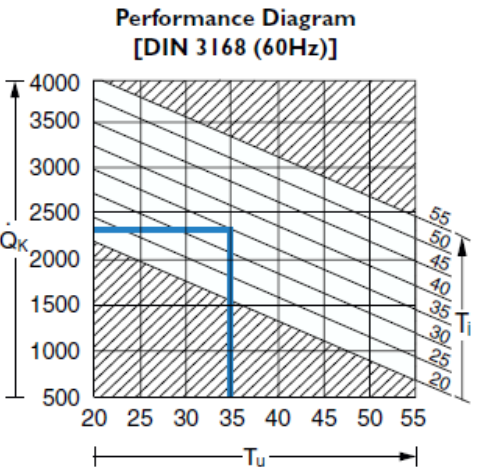

As much as people enjoy warm weather, too much heat can cause our bodies’ systems to decrease our energy outpoint, reducing productivity. Heat is also often an enemy of electrical devices, reducing their efficiency over the long term. In fact, 57 percent of all component failures are due to heat-related issues. Air conditioning offers the fastest way to reduce the high temperatures, humidity, and dust that can lead to electrical equipment failures down the line. Learning how to read an air conditioner performance diagram is your first step toward making smart choices when buying enclosure climate control systems.

Cooling with Filter Fans for Electronic Enclosures

[fa icon="calendar'] Jul 23, 2015 2:01:00 PM / by Rittal North America LLC posted in Data Center Solutions, Industrial Automation

People don’t want to live in dirty environments and neither do electronics. Electronic controls and instrumentation are highly sensitive to factors like dust, oil, high humidity, and excessive heat. Maintaining tight control over temperatures inside an electronics enclosure is essential for protecting these devices. System designers can choose from a variety of cooling options, including natural convection, fans, air-to-air heat exchangers, air-to-water heat exchangers, and air conditioners. Each of these technologies offers its own unique style, advantages, and customization options.

Is it just me or is it really hot in here?

[fa icon="calendar'] Apr 27, 2015 12:45:59 PM / by Rittal North America LLC

Is it just me . . . or is it really hot in here?

Imagine you find yourself locked in a small metal closet with little or no ventilation . . . it wouldn’t take long before you were perspiring profusely and gasping for breath. Well, now imagine that you’re a 19-inch rack stacked with computers and other electronics in that same closet. It wouldn’t take long before excessive heat forced you to shut down completely.

An electronics enclosure is designed to protect electronic components and devices by providing a physical barrier to aggressive media like humidity, water, oil-contaminated air, corrosive vapors, and airborne dust. As threatening as these factors are, the number one enemy of today's high-performance electronic and microelectronic components housed in enclosures is actually excessive heat. As the packing density inside enclosures has increased, so have the importance of heat dissipation and energy efficiency in modern climate control enclosure systems. If exposed to a 10K increase in temperature relative to the maximum permitted operating temperature, an electronic component’s service life can be cut in half and its failure rate doubles. (See the Arrhenius equation below)

Parlez-Vous “Climate Control ”?

[fa icon="calendar'] Apr 27, 2015 11:10:40 AM / by Rittal North America LLC posted in Industrial Automation

Parlez-Vous “Climate Control ”?

Like just about any other category of industrial operating equipment, there’s a unique vocabulary associated with climate control, cabinet ventilation, and enclosure cooling and heating. Learning to speak that language fluently can help you communicate effectively with system designers and contractors, and prevent time-wasting confusion. Here are some of the most commonly used terms you need to know:

Ensuring Electromagnetic Harmony Inside Your Electronics Enclosures

[fa icon="calendar'] Apr 27, 2015 11:06:41 AM / by Rittal North America LLC posted in Industrial Automation

Ensuring Electromagnetic Harmony Inside Your Electronics Enclosures

Is Your Electronic Enclosure Running a Fever?

[fa icon="calendar'] Apr 27, 2015 10:34:00 AM / by Rittal North America LLC posted in Industrial Automation

Electronics enclosures are typically stuffed with electrical gear that generates heat as a by-product of operation, so controlling the temperature within them always involves a careful evaluation of their specific heating and cooling requirements.

When a low-voltage switchgear assembly operates, short-circuit losses can occur, which causes the temperature of the air inside the enclosure to rise. This, in turn, leads to poor heat dissipation from the surfaces of the installed components and assemblies, which can result in costly damage. Hot spots (over-temperatures that occur in isolated locations without natural air movement to dissipate heat) can be particularly troublesome.

Here are some common causes of rising temperatures within enclosures:

- The operating equipment is too densely packed, obstructing airflow, or the components and conductors are incorrectly dimensioned.

- Poor contact between individual live conductors.

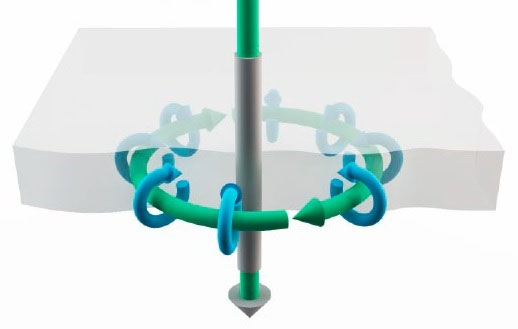

- Particularly in power distributors with high currents, the problem may lie in the formation of eddy currents in the assembly components and metallic surfaces adjacent to the conductors. As illustrated in the following diagram, current-carrying conductors that are inserted from beneath the enclosure through the gland plate can generate a magnetic field in the plate. Heat can be generated as a result of the eddy currents produced by this magnetic field.

Will Your Systems Be Ready When “The Big One” Comes?

[fa icon="calendar'] Apr 24, 2015 10:17:00 AM / by Rittal North America LLC posted in Industrial Automation

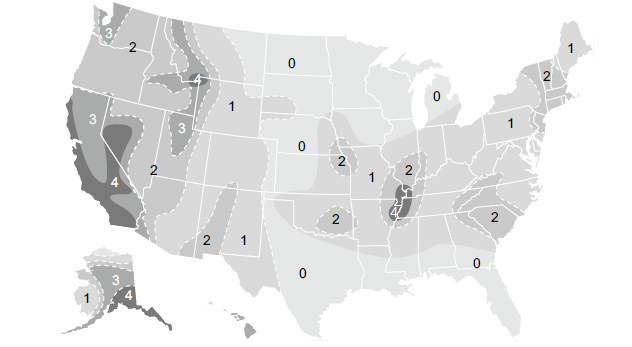

Although Southern California is almost as well known for its earthquakes as it is for sunshine and movie stars, the most powerful quakes are relatively rare. Scientists believe the last mega-quake to hit the region was an 1857 magnitude 7.9 quake. The U.S. Geological Survey recently revised its estimate of how soon the next magnitude 8.0 or greater earthquake is likely to strike California, raising the chance of a mega-quake hitting California within the next three decades from about 4.7% to 7%. A magnitude 8.0 quake would produce 89 times more energy than the 6.7 Northridge earthquake of 1994.

However, California is far from the only state at risk of seismic damage. This map illustrates the various Telcordia Technologies (formerly BELLCORE) risk zones, classified from 0 to 4. Zone 0 has no earthquake activity, while significant earthquake activity is to be expected in zone 4. Enclosures designed for use in earthquake-prone zones must be designed with the stability and strength to withstand extreme dynamic loads, especially where the enclosures house active components.

Why does heat have to be dissipated from an enclosure?

[fa icon="calendar'] Mar 31, 2015 10:54:00 AM / by Rittal North America LLC posted in Industrial Automation

In addition to negative external influences such as oil-contaminated and humid ambient air and dust, heat is the number one enemy of today’s high-performance electronic components in enclosures.

Industry 4.0: coming to a factory near you – including yours!

[fa icon="calendar'] Mar 31, 2015 10:52:00 AM / by Rittal North America LLC posted in Industrial Automation