In food and beverage (F&B) production facilities around the world, cleaning and sanitization are just as vital to an organization’s success as the taste and texture of the products they produce. Although cleaning adds no direct value to a product, the cost of failing to do it properly can be enormous, both in terms of company reputation and the risk of spreading potentially deadly illnesses. Even when working hard to operate in compliance with the strictest standards, U.S. F&B producers are forced to recall thousands of products each year, typically for one of three reasons: undeclared allergens (such as the presence of milk, wheat, peanuts or soy that don’t appear on the label), pathogens like E.coli, salmonella or listeria, or physical contamination.

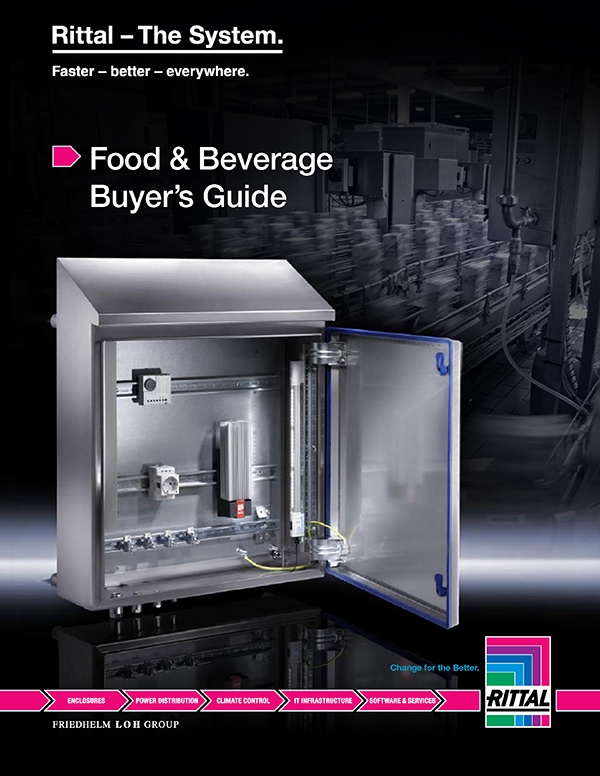

CLICK HERE TO DOWNLOAD YOUR FOOD & BEVERAGE BUYER'S GUIDE

All U.S. F&B processors are affected by increasingly stringent food safety standards. These standards