Ensuring Electromagnetic Harmony Inside Your Electronics Enclosures

Ensuring Electromagnetic Harmony Inside Your Electronics Enclosures

[fa icon="calendar'] Apr 27, 2015 11:06:41 AM / by Rittal North America LLC posted in Industrial Automation

Is Your Electronic Enclosure Running a Fever?

[fa icon="calendar'] Apr 27, 2015 10:34:00 AM / by Rittal North America LLC posted in Industrial Automation

Electronics enclosures are typically stuffed with electrical gear that generates heat as a by-product of operation, so controlling the temperature within them always involves a careful evaluation of their specific heating and cooling requirements.

When a low-voltage switchgear assembly operates, short-circuit losses can occur, which causes the temperature of the air inside the enclosure to rise. This, in turn, leads to poor heat dissipation from the surfaces of the installed components and assemblies, which can result in costly damage. Hot spots (over-temperatures that occur in isolated locations without natural air movement to dissipate heat) can be particularly troublesome.

Here are some common causes of rising temperatures within enclosures:

- The operating equipment is too densely packed, obstructing airflow, or the components and conductors are incorrectly dimensioned.

- Poor contact between individual live conductors.

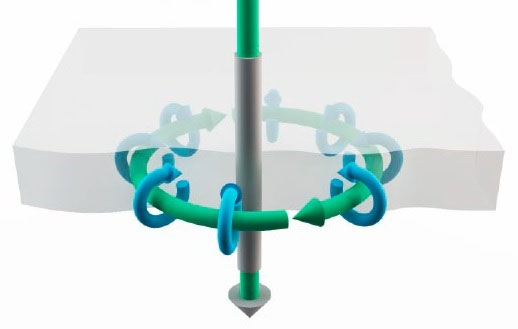

- Particularly in power distributors with high currents, the problem may lie in the formation of eddy currents in the assembly components and metallic surfaces adjacent to the conductors. As illustrated in the following diagram, current-carrying conductors that are inserted from beneath the enclosure through the gland plate can generate a magnetic field in the plate. Heat can be generated as a result of the eddy currents produced by this magnetic field.

Will Your Systems Be Ready When “The Big One” Comes?

[fa icon="calendar'] Apr 24, 2015 10:17:00 AM / by Rittal North America LLC posted in Industrial Automation

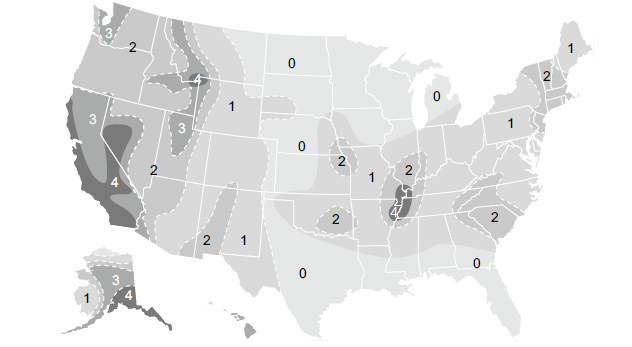

Although Southern California is almost as well known for its earthquakes as it is for sunshine and movie stars, the most powerful quakes are relatively rare. Scientists believe the last mega-quake to hit the region was an 1857 magnitude 7.9 quake. The U.S. Geological Survey recently revised its estimate of how soon the next magnitude 8.0 or greater earthquake is likely to strike California, raising the chance of a mega-quake hitting California within the next three decades from about 4.7% to 7%. A magnitude 8.0 quake would produce 89 times more energy than the 6.7 Northridge earthquake of 1994.

However, California is far from the only state at risk of seismic damage. This map illustrates the various Telcordia Technologies (formerly BELLCORE) risk zones, classified from 0 to 4. Zone 0 has no earthquake activity, while significant earthquake activity is to be expected in zone 4. Enclosures designed for use in earthquake-prone zones must be designed with the stability and strength to withstand extreme dynamic loads, especially where the enclosures house active components.

Why does heat have to be dissipated from an enclosure?

[fa icon="calendar'] Mar 31, 2015 10:54:00 AM / by Rittal North America LLC posted in Industrial Automation

In addition to negative external influences such as oil-contaminated and humid ambient air and dust, heat is the number one enemy of today’s high-performance electronic components in enclosures.

Industry 4.0: coming to a factory near you – including yours!

[fa icon="calendar'] Mar 31, 2015 10:52:00 AM / by Rittal North America LLC posted in Industrial Automation

Big data becomes huge data. What it means for IT enclosure design.

[fa icon="calendar'] Mar 31, 2015 10:44:00 AM / by Rittal North America LLC posted in Data Center Solutions, Industrial Automation

It’s tough for data center engineers and designers to manage the impact of Big Data and the resulting rapid growth in data centers that’s creating. Traditional data centers are giving way to new IT spaces, and that’s creating demand for different approaches to IT enclosure design.