Climate Control Case Study: How to Cool a High-Density Data Application

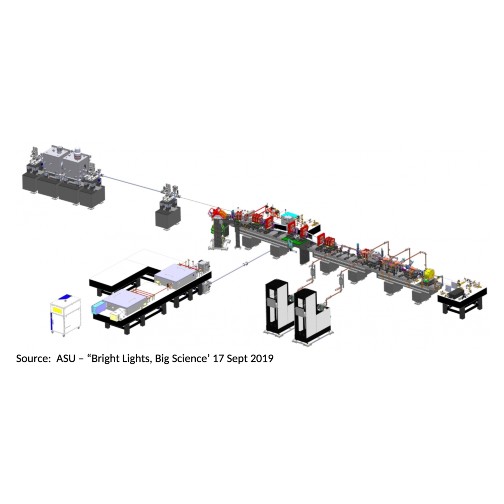

There are relatively simple server enclosure cooling needs...and then there’s the challenge posed by Arizona State University’s (ASU) Compact X-ray Free Electron Laser (CXFEL). For the best cooling solution to control the climate around the world’s first CXFEL’s high-density servers, ASU chose to partner with Rittal.

Challenge

ASU’s CXFEL is a revolutionary new laser diagnostic tool that promises to be a force-multiplier for discovery, accelerating research and new treatments for cancer and other diseases. This instrument pushes the boundaries of diagnostic research imaging in order to aid scientists in better understanding the cellular mechanics of diseases.

Building and installing the CXFEL came with several notable challenges; among them were the need to support the IT appliances necessary to control the laser, and to store the massive amount of data it would produce.

Climate Control Needs

- ASU saw that the only solution that could support the project criteria would be a high-density installation in close proximity to the laser, in order to reduce latency and improve real-time analysis

- This type of system would need to be supported by the highest-capacity closed-loop climate control system to ensure optimum performance and uptime, and prevent server overheating and failure

The Solution

One installation option ASU briefly considered was to design and build a separate high-density data center to support the CXFEL. This was rejected after determining that it would be too costly – and, ultimately, unnecessary.

The best solution was to utilize a standard server rack that supported a significantly higher installation density, with a built-in high-performance cooling system. ASU worked closely with a Rittal Account Manager and, with their help, implemented the Rittal LCP CW HD closed-loop system.

Benefits

Here are some of the features that made Rittal’s LCP CW HD closed-loop system the right choice for ASU:

- Closed airflow loop system. Instead of operating as a traditional system in a typical cold aisle/hot aisle configuration, the Rittal LCP CW HD uses a closed airflow loop, meaning all cold air and hot air is contained within the suite – no air is rejected into external spaces

- Maximum heat removal. Being self-contained allows Rittal to harness the power of the air-to-water heat exchanger to maximize heat removal capacity up to 60kW in each system. Higher heat removal capacity enables higher installation densities, reducing the number of server enclosures required to support the CXFEL

- Space-saving. The LCP CW HD enclosure has a capacity of up to 60kW, yet has the same footprint as enclosures that have just 20kW of capacity

- It’s future-proof. The LCP CW HD can be retrofitted to accommodate new equipment, making it an even more cost-effective solution

- No fans. Because it’s a closed-loop system, it’s exceptionally quiet – there are no loud fans usually associated with high-density cooling

- Improved efficiencies. Efficiency is increased when using higher LCP HD supply-water temperature, as well as warmer server air inlet temperatures, while still conforming to ASHRAE TC 9.9 standards. A higher water inlet temperature increases the proportion of free cooling, reducing operating costs

The Results

Working with Rittal, ASU accomplished its Edge computing goals: to bring critical data as close to the instrument as possible to reduce latency and improve real-time analysis, and mitigate risks of downtime. With the Rittal system, all the power, efficiency and reliability is on-site, at a fraction of time and costs compared to traditional climate control and heat removal systems.

A total of 3 Rittal LCP systems have been installed in the ASU lab, supporting the cutting-edge CXFEL and the experiments being performed. Together, they have the potential to make huge advancements in life sciences.

Learn more about the best cooling solutions for high-density Edge computing by downloading our “Industry 4.0 at the Edge” brochure.