While the events of the last 18 months have certainly created new and challenging problems for the world to solve, what’s flown a little beneath the radar is the existing problems that simply have been exacerbated or accelerated by the global pandemic.

This is certainly true with the U.S. manufacturing landscape and its significant labor shortage. A recent study conducted by The Workforce Institute at UKG revealed that while the U.S. manufacturing sector has certainly bounced back since losing around 30% of its shifts in mid-April 2020, nearly two-thirds of manufacturers are still struggling to fill labor gaps.

But the storm of a significant labor shortage in the manufacturing space was already brewing prior to COVID-19. According to a report issued by Deloitte and The Manufacturing Institute, U.S. manufacturers were facing a labor shortage of roughly 4 million jobs by 2030, which means these companies were already grappling with a massive shortage in the near future.

Rittal Automation Systems (RAS) helps systems integrators, control panel manufacturers, and OEMs streamline the manual tasks that once required high degrees of human intervention, while also optimizing the precision of panel production and modification. Let’s dive into the products and solutions that make up RAS as well as their real-world value to understand how RAS can help manufacturers navigate today and tomorrow’s labor shortages.

What is RAS?

RAS is a suite of solutions from tools to fully-automated machines that support industrial panel modification and switchgear assembly. RAS machines are engineered for precise cutting, tapping, milling, and wire processing, which manufacturers in virtually every industry encounter as industrial automation applications become more varied and unique. The variety and flexibility of modifications or wire processing allows for repeatability and scalability based on customer or market demands.

The primary market force with the labor shortage is two-fold: the first being not enough automation installed (particularly in the modification and wiring of control panels), and the second being the lack of a labor force to facilitate panel assembly and modification.

An important value proposition of RAS is the high volume of specialized, precise, and rapid assembly and modification processes that can be achieved with a reduced workforce — to say nothing of wire processing capabilities. The backbone of the RAS line includes:

- Perforex MT milling terminal : The Perforex MT provides fully-automated, fast, precise, and reliable machining (drilling, thread-tapping, and milling) of mounting plates, doors, roof plates, side panels, gland plates, or unibody enclosures. The Perforex MT also leverages an intuitive user interface that makes it fast and easy to operate the machine.

- Perforex LC laser center: Built for stainless and sheet metal applications, the Perforex LC uses laser cutting technology for precision, speed, and optimized machining of up to 5 surfaces simultaneously. The LC completes highly-customizable machining and can run up to 20x faster than conventional milling processes with easy loading for increased ergonomics.

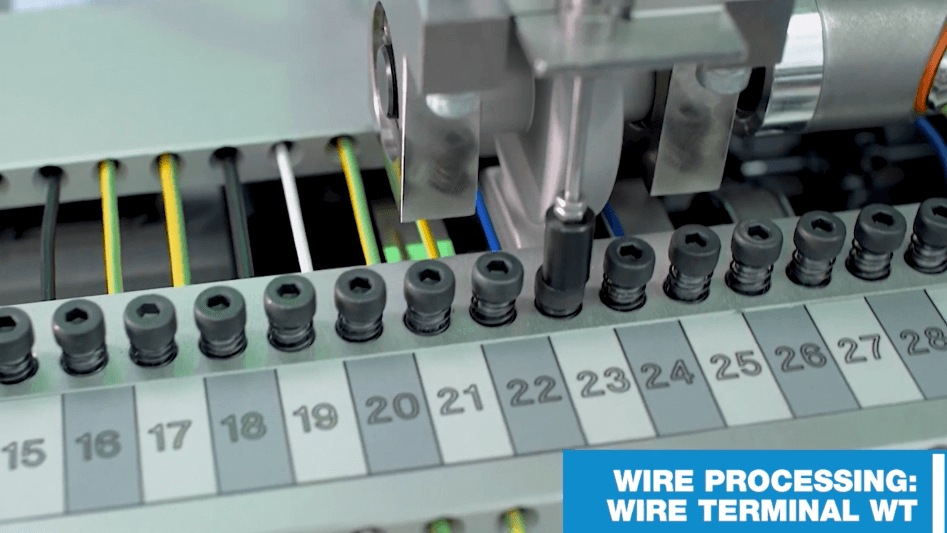

- Wire Terminal WT: The Wire Terminal WT processing and assembly machine can produce 24 to 36 different wires with cross-sections ranging from 0.5 mm² to 6 mm². The variety of wire assembly, easy job setup and modification, and compact nature of the machine helps manufacturers with high volumes of wire processing jobs work faster and more precisely.

RAS also includes a variety of semi-automatic wire-processing machines to virtually eliminate the manual processes of wire stripping, crimping, and other time-consuming tasks. These machines reduce the time it takes to manually manipulate wire tasks by 70%, which means more wires can be processed with fewer interventions and fewer technicians on the floor.

While on the surface these automation tools might seem like technology taking jobs from actual workers, it’s actually an enhancement that helps companies hit production goals and drive profitability, as well as withstand potential production gaps due to labor shortages. With RAS, companies can reallocate valuable skilled labor to tasks that require human intervention or complex decision making.

What is the value RAS provides manufacturers?

What are the real-world benefits RAS provides manufacturers? How does RAS help manufacturers navigate the labor shortage on a day-in, day-out basis? The demand for manufacturing in the U.S. is outpacing production, which is resulting in longer lead times, delayed delivery windows, and slowed growth.

Imagine you receive an order for 10 modified enclosures, which, depending on the nature of the order, can take up to 45 minutes each to manually complete.

That means without any troubleshooting or challenges along the way, you’re looking at 450 minutes to complete the entire order.

That’s 7.5 hours of production time, much of which could take multiple workers.

Now, imagine machining the same order with a RAS machine like the Perforex, which can slash production time to a mere 3 minutes per enclosure with significantly increased precision.

That’s 30 minutes of production time for the entire order.

Multiply this scenario by five times and it’s easy to see how using a RAS tool for machining or wire processing provides real-world value in an industrial marketplace where labor is in high demand and speed is critical. Other concrete value propositions include:

- Elimination of the manual processes that are costly and time-intensive.

- Reduction in machining or modification costs via reducing human error found in manual tasks.

- More precise, complex machining for a wider variety of industrial or manufacturing applications.

- A more fully-automated industrial ecosystem that provides deeper, more profound insight into your holistic panel and switchgear production process.

With Rittal Automation Systems, a route for navigating the labor shortage with speed, precision, and an optimized automation architecture is more accessible and valuable than ever before.

Learn more about how Rittal Automation Systems can help you increase your panel building efficiency by 85%!