Supply chains rely on warehouses to deliver products accurately and on time. And efficiency is key to maintaining business relationships and customer satisfaction. But with challenges like increased expectations for customer delivery, labor shortages, and keeping costs down, how can your warehouse increase effectiveness?

The answer lies in an unexpected place — your data and technology. In fact, Industry 4.0 is driven by widening networks, automation, analytics, and human to machine interactions. Utilizing a dataset that can be analyzed by artificially intelligent systems to detect problems from machine defects to predicting when a component will need to be fixed can open doors to smoother processes. In spite of this, companies have been slow to adopt — many businesses have remained in their comfort zone, opting to retain outdated supply chain management systems. In fact, only 30% of manufacturers have reported being up to date with Industry 4.0. Keeping up with the speed of change can be daunting, but here are ways that you can bring your warehouse up to date with Industry 4.0 and all the innovation that brings.

Adopt New Technology

In order for warehouses to survive and thrive, they must adapt to new technologies. But with challenges like working with limited budgets and time, staying up to date can be overwhelming. One great starting point is migrating the data you already manage into the cloud.

The cloud is an essential part of Industry 4.0, as it opens up opportunities for companies to have instant access to their data on multiple machines and platforms. It also increases interoperability, which is when data can be transferred and accessed between organizations and locations. This can enable you to send vital information between facilities and stakeholders faster than ever before.

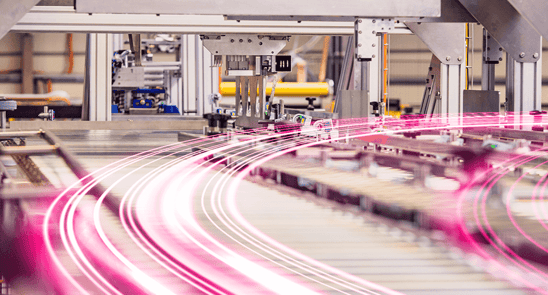

Embrace automation

When moving beyond cloud migration, enabling automation, artificial intelligence (AI), and machine learning will push innovation and efficiency in your warehouse even further. With your data in the cloud, the AI system you choose will already have a vast data bank from which it can derive essential patterns. Like a person, the machine learning portion of AI can learn from information it receives, but at a vastly faster pace than any human. This technology can inform you of when machines will need routine repair before they begin to break down, and can even predict inventory discrepancies.

Naturally, concerns surrounding a reduction in human workforce arise when considering the impact of automation on a warehouse. But in recent years, robots in a warehouse haven’t been used so much to replace people, but rather to work together with them to increase efficiency and reduce both risk and cost. The benefits of AI in a warehouse, whether being used in physical form to lift heavy loads, or as software to analyze data, carries a number of benefits:

- Increased productivity

- Improved data accuracy

- Reduced safety risks

- Minimized expenses

Inventory issues like out of stock products and overstock are costly — in 2018, retail giant H&M lost $4 billion in unsold merchandise. And according to a study published by IHL Group, inventory distortion costs companies over $818 billion yearly:

- 56% from out of stock products, totalling $456.3 billion

- 44% from overstock, totalling $362.1 billion

Applying data and predictive analysis from AI can drastically reduce the cost of unused or overstock inventory.

Automation can be extremely lucrative for manufacturers. Alibaba, the retail giant from China, maintains the world’s largest automated warehouse, equipped with 700 robots which perform 70% of the work, such as carrying heavy loads and managing stock. Because of the level of efficiency Alibaba has achieved by using automation, the company made $248 billion in transactions in the year 2018 alone, more than Amazon and eBay combined.

With benefits like reducing the risk of overstock and out of stock products, predictive analysis, and improved communication between facilities, utilizing data and updating technology in your warehouse is key to improving efficiency

Rittal is a worldwide leader in climate-control enclosures and innovation. Learn more about Rittal’s climate control solutions, including our NEMA-rated enclosures and our power distribution and climate control solutions. Partner with us to increase your warehouse's efficiency and reap the full benefits of Industry 4.0