For Gartner Elektrotechnik it is clear: If you want to grow, you have to invest - in people, infrastructure, and machines. That is why the Upper Austrian plant manufacturer commissioned the 3D laser processing center Perforex LC 3015 from Rittal in August 2017 and is thus focusing on process automation and further growth. To program the laser, the company uses the EPLAN Pro Panel software, a CAE solution for 3D engineering of control cabinets.

“One of the biggest challenges in switch cabinet construction is to optimize the manufacturing processes, both in terms of quality and time. That's why we decided that the machine and software should come from a single source. So we only have one contact person and can assume that all processes and cycles fit together. We have found the ideal partners for this in Rittal and EPLAN.” - Friedrich Gartner, Managing Director at Gartner Elektrotechnik GmbHInvestment in the future

"Anyone who is or wants to be in switch cabinet construction must invest in the future," explains Friedrich Gartner.

The entrepreneur is able to do this with the help of automation, among other things, to simplify and accelerate production processes. Gartner Elektrotechnik found the ideal solution in the Perforex LC 3015 3D laser processing center from Rittal. While the processing of stainless-steel surfaces was previously associated with high tool wear, longer processing times, and a high level of noise, processing using laser technology with the Perforex LC 3015 is contactless, fast and low-vibration - without tarnishing and discoloration of cut edges. In addition, a large part of the manual post-processing such as deburring is no longer necessary.

The materials to be processed no longer have to be clamped, but only placed on the surface of the machine and thus contribute to further process acceleration. This increases quality and saves time.

Fast commissioning

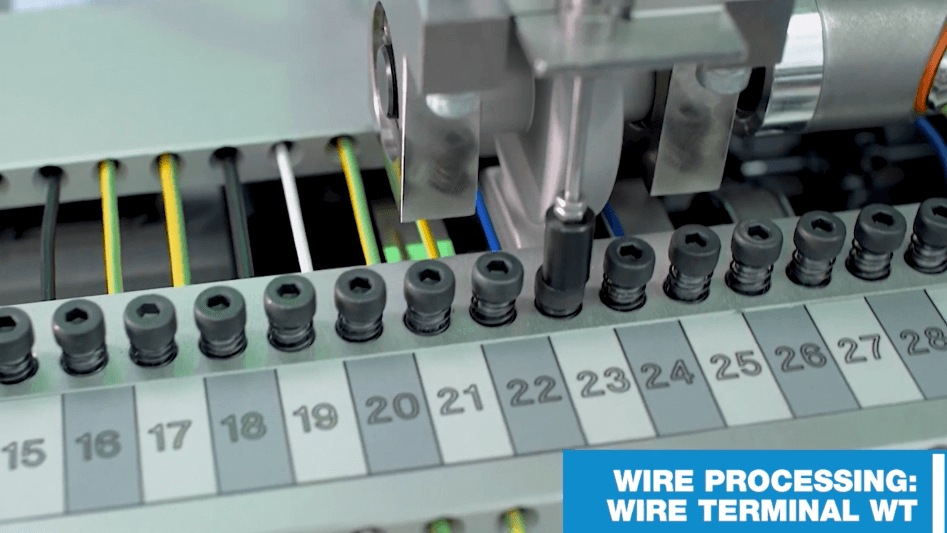

The laser has been in use at Gartner Elektrotechnik since August 2017. The programming of the Perforex can either be based on simple and component-oriented workshop programming or using imported CAE data, e.g. from EPLAN Pro Panel software, as with Gartner Elektrotechnik. The CAE solution for 3D engineering of control cabinets and switchgear ensures that the control engineering project planning and the 3D control cabinet design are directly linked.

Gartner is very satisfied with its decision to work with Rittal and EPLAN and is optimistic about the future: “We are a growing company. Every year we achieve increases of between 15 and 25 percent. Thanks to the laser processing center, we are confident that we can do it again.”

The Perforex LC 3030 is the current model, an updated version of the Perforex LC 3015 which has been phased out. It can accommodate stainless steel, sheet steel, and aluminum. Machining speed can be completed 20X faster than with conventional milling processes when using stainless steel. Features ergonomic working, thanks to the extendible support surface for enclosure and panel machining

The Perforex laser center is specially designed for the automated mechanical modification of standard. Additional benefits include:

- 3D laser machining of cubes, simultaneous machining of 5 sides

- 3D enclosure machining without repositioning the workpiece

- Product spectrum from compact to large enclosures

- Contactless, low vibration machining with no tool wear

- No need to clamp the workpieces

- No tarnishing or discoloration of the cut edges when machining stainless steel

- Spray-finished metal parts, even delicate contours, can be cut without damaging the paint or causing discoloration

Together, Rittal and EPLAN can simplify your business, watch the video to learn how.