Industrial enclosures keep your business running by protecting your critical process equipment. Without quality enclosures, your systems will be left vulnerable, risking downtime and lost productivity. That’s why it’s important that you get the right one… and quickly.

To make sure that you get the best enclosure for your specific needs, you need to ask the right questions. Here are the questions that should be on the top of your mind when specifying an enclosure:

Where will the Enclosure Be?

The environment in which your enclosure is located will directly impact the requirements of the enclosure. For instance, outdoor enclosures have different requirements than indoor enclosures, leading to different material considerations. Painted carbon steel is the most cost-effective metallic enclosure material, and as such, is the go-to material for typical indoor applications. However, harsher outdoor environments may require a heavier carbon or stainless-steel enclosure in order for it to hold up against weather and tampering issues.

Where an enclosure is will also influence your climate control requirements. Top climate control solutions for industrial enclosures include:

- Air conditioners

- Heat exchangers

- Filter fans

- Chillers

- Thermoelectric coolers

What Hazards/Contaminants will the Enclosure be Subjected To?

Above all else, your enclosure needs to be able to protect the critical process components inside it. Apart from unauthorized access and enclosure tampering, protecting your equipment is all about an enclosure’s ability to withstand the environmental hazards and contaminants that it’s subjected to. In this way, an enclosure’s level of protection can be simply defined by its NEMA rating. NEMA ratings define what types of environments you can use an enclosure in, signifying its ability to withstand certain hazardous conditions. Common NEMA ratings for industrial applications are:

- Type 1: for basic protection

- Type 3: for protection against windblown dust, rain, sleet, and external ice formation

- Type 4: for protection against washdowns and pressurized water streams

- Type 5: for protection against settling airborne dust, falling dirt, and dripping non-corrosive liquids

How Big Does the Enclosure Need to Be?

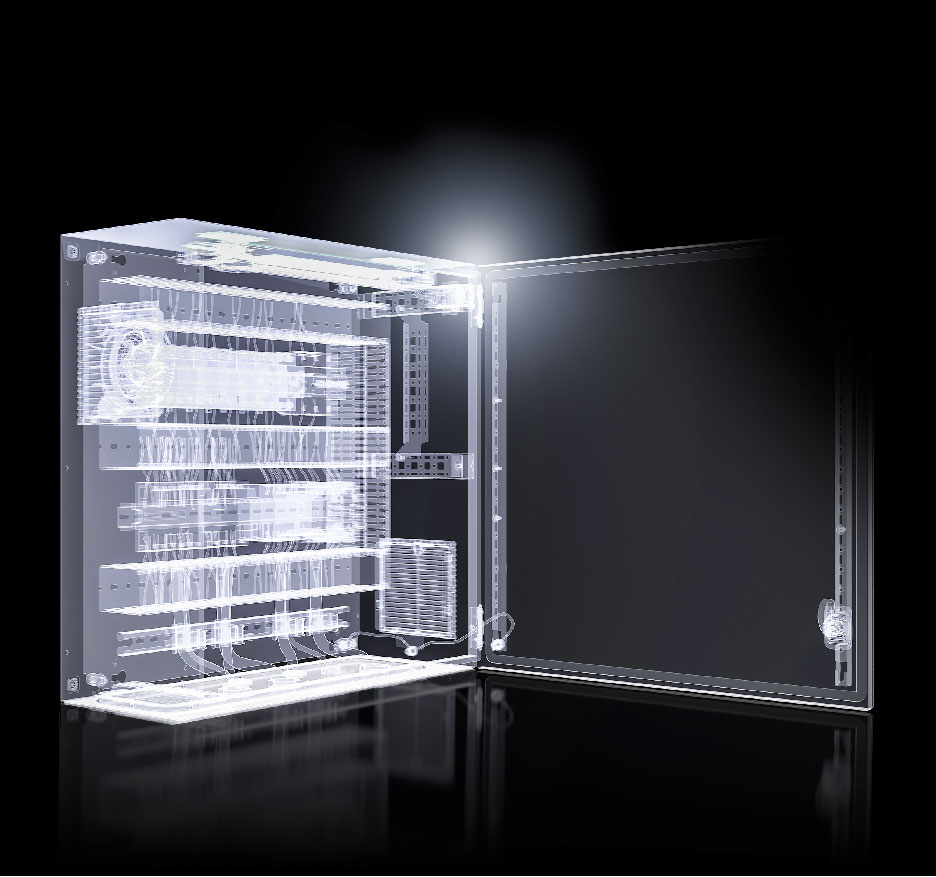

Finding an enclosure with the right dimensions will ensure that it has the capacity to hold and protect your critical process equipment. You need to make sure that it has enough space, not only for today, but for whatever the enclosure may need to hold in the future as your business evolves. However, this isn’t just about the physical space necessary to fit your components. Other considerations like heat dissipation, venting and cables/wiring will take up internal space. Subpanel mounting also takes up a small portion of the space, as well as any pushbuttons, operator interfaces, meters, or status indicators that you plan to mount on the enclosure door. All of these things need to be accounted for when specifying the size of your enclosure.

Knowing the size of your enclosure will also help to determine if you need a single-door or two-door design, as well as if you should get a wall-mount, floor-mount or freestanding enclosure. Choosing between a modular design and a typical unibody weld is also important to your enclosure’s performance. Modular designs are becoming increasingly popular due to their ability to maximize internal space, taking up less room on the plant floor than bulky unibody enclosures.

Who Needs Access to the Enclosure?

To ensure that your process equipment is functionality properly, technicians and operators need to be able to get inside your enclosure at regular intervals. However, you still need to prevent unauthorized access, especially in outdoor or less secure environments. Outfitting your enclosure with additional security features like custom lock inserts, specialty handles and padlock accessories help ensure that only the right people have access.

What are My Installation and Maintenance Requirements?

It’s simple – heavy enclosures are difficult to move. Not only will a heavy enclosure be difficult to install, requiring cranes and forklifts to move it around the plant, but it will also make it hard for your technicians to perform routine maintenance. With traditional welded boxes, you have to lay the enclosure down on its back to re-configure or replace any wiring. What would be a 10-minute job quickly turns into an hour or more of having to borrow a crane to carefully lift the enclosure, place it on its back and then put it upright again after the wiring is complete.

Modular Enclosure Spotlight

In addition to their ability to maximize internal space, modular designs also add great value when it comes to enclosure access and maintenance. If you need to work on a modular cabinet, you can simply slide the mounting panel out of the way and work on the internal components. You can also switch out panels or create hybrid designs, expanding on your enclosure as your needs change over time. And, when your enclosure gets damaged (even the best ones do), you can simply change out the damaged pieces rather than throwing away the whole enclosure.

Do I Need any Accessories?

Getting a base enclosure is just the beginning. In order to optimize the performance of your enclosure, there are a number of standard and custom accessories that you can add into your design. These can include:

- Viewing windows

- Door stops

- Print pockets

- Drip shields

- Swing panels

Once you’ve answered all of the above questions, you’ll be able to pick an enclosure that you can trust to keep your components safe and your systems operational.

Get the Perfect Enclosure in Half the Time

Even the best enclosure designs can’t protect your systems if they’re stuck in production. That’s why you need to find an enclosure supplier that moves just as fast as you do.

In order to help the design engineers of tomorrow, Rittal has teamed up with EPLAN to offer a complete “end-to-end” solution for enclosure selection and panel building. Together, Rittal’s automated systems and EPLAN’s software solutions ensure that you get the enclosure you need in half the time. Here’s how we do it:

Digital Twins and Online Enclosure Configuration

With Rittal’s online enclosure configuration software, you can build a digital, CAD-based twin of your enclosure. Digital twins allow you to easily make modifications and customize your enclosure without having to waste time and materials working with a physical model. These custom enclosures offer significant gains in efficiency and performance, leading to better protection for your critical process equipment.

Fast Modifications and Delivery

In addition to setting the standard for industrial enclosures, Rittal’s automated systems can make custom enclosure modifications in minutes instead of hours. This allows us to drastically reduce lead times, getting you the enclosures that you need sooner than anyone else on the market. Our automated systems are also more accurate, efficient and reliable than manual machining, cutting down on cost and waste.

Easy Assembly and Wiring

Rittal’s custom modular enclosures are shipped loose, allowing for effortless installation. With the integration of the digital twin, your operators will get detailed and easy-to-follow assembly instructions so that they can reliably set up your enclosure in a fraction of the time. Even panel building and wiring is made easy with EPLAN’s Smart Wiring app. Made for panel builders, this helpful app allows your operators to visualize every step in the wiring process, from the connection point to the exact wire routing. By providing digital engineering data and documenting whenever a connection is made, the Smart Wiring app makes wiring simple.

With the power of Rittal’s online enclosure configurations, fast deliveries, and easy assemblies, it’s not uncommon for you to get the enclosure that you need up-and-running in less time than it would take for one of our competitors to give you a quote. That’s why Rittal enclosures are fueling the fast-paced businesses of Industry 4.0.

Click here to learn more about Rittal’s automated systems.