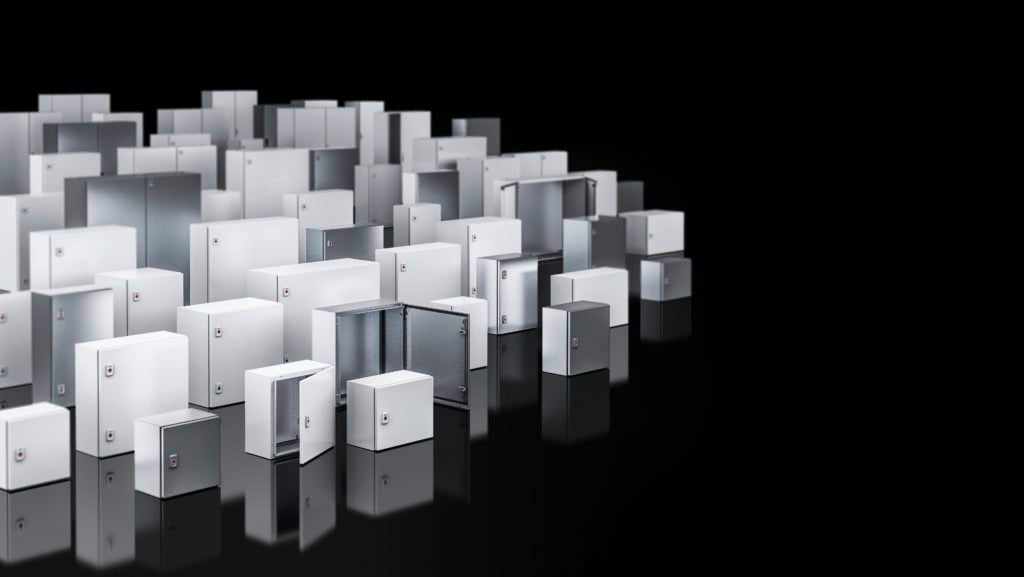

Every enclosure represents a unique challenge. Power systems, lighting, wiring, door configuration, and cooling units all require custom modifications. Full automation of the process increases accuracy and improves the turnaround time.

The repetitive labor routines, high production costs and longer lead times required by traditional panel-building practices can now be replaced with a far more streamlined “Industry 4.0” value chain. From end-to-end, CAD to final shipment, only Rittal offers the complete portfolio of design-to-production capabilities to make Industry 4.0 truly seamless and truly simple.

Rittal has automated panel building and switchgear engineering with a comprehensive range of solutions from manual tools to fully mechanical engineering solutions. Rittal can assist in implementing the exact modifications for individual panels.

- Machining: Fully automated, fast, precise and reliable milling or laser machining of enclosures and cases, plus cut-optimized machining of cable ducts and DIN rails.

- Assembly: Enhanced efficiency with automated production of clamping strips and ergonomic component mounting systems.

- Wire Processing: Professional and practical solutions for wire machining and processing featuring simple and reliable handling.

- Wiring: Fully automated wiring of mounting plates offers efficient wiring and intuitive control.

- Tools: High-quality manual tools available for use by those with high professional standards.

- Handling: Ergonomic, efficient design of tools and machines.

The Heart of the Automated System: Perforex

Perform 10 hours of panel production work in just 90 minutes. That is the reality of Perforex. Perforex delivers not only time savings but increased accuracy and reduced waste with its laser precision-capabilities. The more complex the panel, the more it boosts your efficiency. Perforex units call upon up to 20 tools in the magazine for operations including drilling tapping, milling and circular thread milling,

Perforex can handle clampable panels up to 2200×1500 mm, and since programming is faster than manual marking, the system is economically advantageous from a batch size of one. Perhaps most importantly, there are important design advantages inherent in Rittal enclosures that are amplified with the Perforex machining center.

The Rittal Automation Systems Plan

Faster throughput. Higher Efficiency. Greater precision. Less waste. Lower cost. Rittal Automation Systems is the only company in the world able to deliver it all to you from a single source, with seamless integration and specific advantages every step of the way. No patchwork solution, no complex integration of various vendors to manage.

See how Rittal is engineered better. Download our Change for the Better Fact Book to see how Rittal products are better than the competition!