When it comes to wallmount enclosures, there’s no “one-size-fits-all” approach. You have to customize your enclosure to fit the unique needs of your specific application. Wall-mounted enclosures must be designed, manufactured, and modified within tight tolerances in order to achieve optimal enclosure performance.

For design engineers and plant managers alike, this all means a number of challenges, including:

- Higher costs

- Longer lead times

- Painstaking design processes

- Regulatory issues

That’s why you need to simplify your process as much as you can. When choosing an enclosure provider, you’ll want to go with ones who use automation to drive changes in the enclosure design process. You’ll want to look for partners with significant experience in technical consulting, virtual prototyping and CAD-driven modification, as well as installation and maintenance support.

Technical Consulting

Finding a partner with significant experience in technical consulting and product design will prove invaluable. You need to know more than just the product specs of a wallmount – you need to know how it will integrate into your systems. Get that wrong and your enclosure might not hold up for its intended product life, or worse, fail to protect your equipment entirely.

The right partner will analyze your unique application and make sure that your wall-mounted enclosure meets your specific needs. In fact, while the natural focus of a company is to find the right customer, finding the perfect supplier is just as important. Having a good relationship with your supplier goes beyond quality enclosures and technical consulting. A strategic supplier will offer:

- Timely enclosure modifications and delivery

- Increased customer satisfaction

- Better business opportunities

- Lower costs by eliminating production mistakes

Achieving Great Supplier Relations: Finding a reliable supplier isn’t easy. According to a report from Efficio Consulting, the vast majority of companies do little to nothing to find the right partner or enhance their supplier relationships. However, this is a two-way street. Suppliers are equally responsible for this severe lack of strategic partnerships. Make sure you find a supplier that is just as committed to your success as you are.

Virtual Prototyping and CAD-driven Enclosure Modification

Gone are the days when each prototype had to be physically made in order to test its performance. Now, computer-aided engineering software allows us to validate a design before committing to the final product. Providers well-versed in virtual prototyping can go through the entire enclosure design and documentation process online in a fraction of the time.

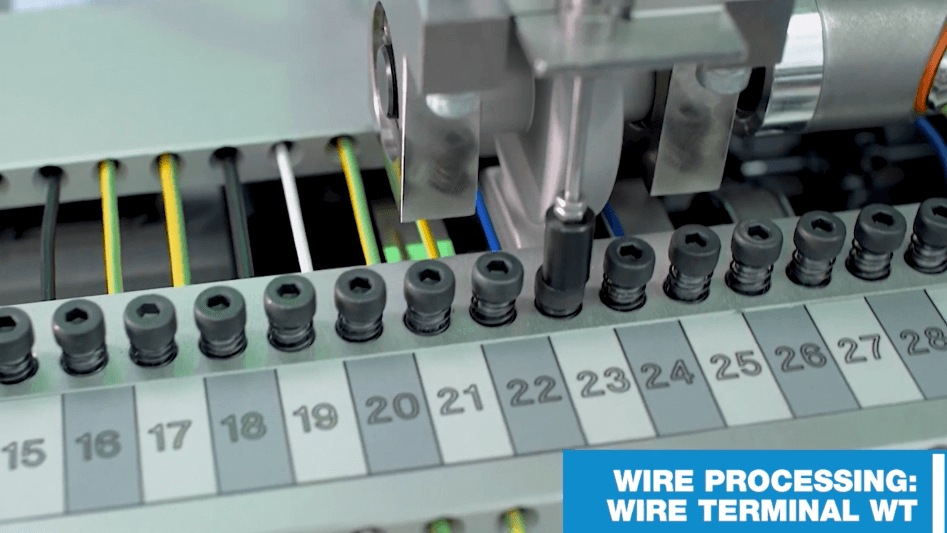

After finding the right design, CAD-driven software can be used for seamless and automated enclosure modifications. This also applies to wiring and terminal assembly. Having a provider that can innovate in the modification space and automate this process means less process downtime and quicker responses to any enclosure issues.

By having a “digital twin” of your enclosure, you can easily identify design errors early on when they are the easiest to fix and the least expensive. Other advantages of virtual prototyping and online configuration systems include:

- Increased enclosure customization and performance

- Seamless accessory integration

- Clear and easy to maintain IP, UL, and NEMA ratings

- Automatically generated assembly instructions for final designs

Installation and Maintenance Support

Getting a system up-and-running – and keeping it that way – requires a certain amount of expertise and “in the field” experience. If you install an enclosure incorrectly, you can compromise its integrity, limiting its ability to protect your equipment. A good partner will make sure that your enclosure is installed correctly, every time.

After your wallmount enclosure is installed, it will eventually require maintenance and proper upkeep. This will help prevent premature failure or untimely degradation of the enclosure’s integrity. Even with proper maintenance, you can’t guarantee that everything will always go your way – make sure to find a provider that knows their way around an enclosure at every stage of its life.

A Better Approach

At Rittal, we’re taking a better and more automated approach to designing and specifying enclosures. With our expert team at the helm, we can deliver a holistic, digital approach to the enclosure selection process, shortening delivery times and ensuring design accuracy. The only thing that can match our efficiency is the quality of our enclosures.

In addition to streamlining your wallmount design process, Rittal offers unmatched expertise for all of your wallmount enclosure needs. Want to make sure you’re getting the best wall-mounted enclosure possible? Our Wallmount Buyer’s Guide contains everything that you need to know about the wallmount selection process.

Click here to get our Wallmount Buyer’s Guide.