In the past, the case for offshore manufacturing for North American companies may have initially seemed to make sense for some. Labor was inexpensive, emerging markets across the globe were building robust infrastructure to facilitate freight and trade of goods and products, and faster, more efficient methods of communication and logistics were making it easier than ever before for companies to create a global footprint.

But what initially sounds good at first glance doesn’t necessarily pan out once you put the details on paper. During the last 10+ years North American manufacturing companies have realized the value in reshoring both on paper and in reality. Along with helping to create a workforce trained in skilled manufacturing, reducing trade and budget deficits, and cutting unemployment rates, the move toward reshoring has also helped companies increase their efficiency and productivity by reducing lead times, cutting shipping costs, and enhancing safe production processes.

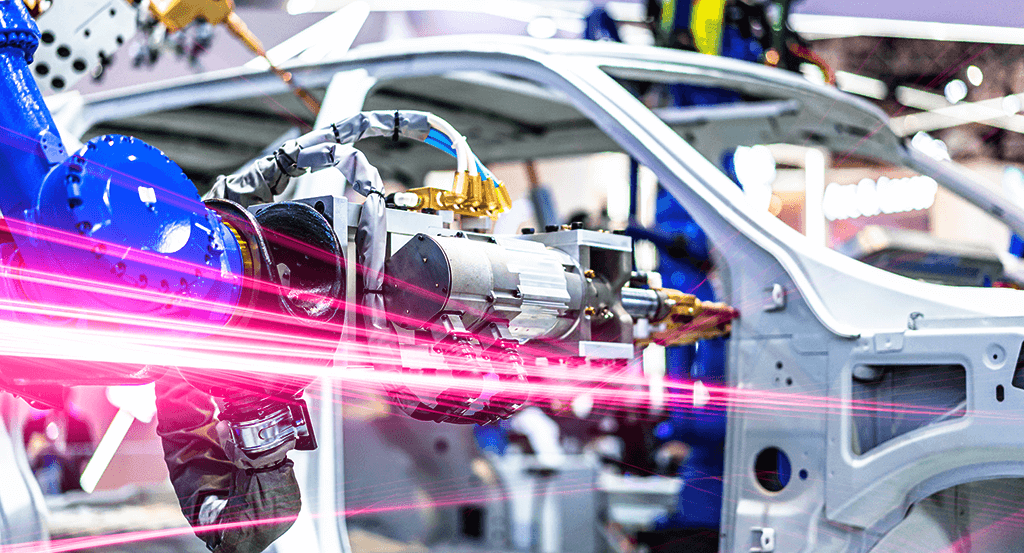

Add to this an emphasis on Industry 4.0, IIoT, and industrial automation frameworks across a variety of industries and you have a recipe for a fascinating shift in how things are made, where things are made, and how products arrive at the end user. To better understand these relationships, let’s examine how reshoring is affecting industrial automation in the U.S, and the important takeaways for today’s manufacturers.

Accelerated shift toward reshoring and automation

In any discussion of reshoring and industrial automation, especially the rate at which both have accelerated in the last 18 months, you can’t ignore the elephant in the room that is the COVID-19 pandemic.

While North American manufacturing companies were making some strides in bringing advanced manufacturing processes back from overseas and looking at ways to increase their automation infrastructure, the instability of the global supply chain, labor and material shortages, and shifts in consumer demand was a massive incentive for manufacturers to move faster and more deliberately in both of these arenas.

An article recently published in Design News dissecting a survey of 100 manufacturing CFOs revealed just how much the pandemic accelerated the shift toward faster, data-driven decision making via automation. 38% of CFOs reported the pandemic led to product or service innovation through some kind of automation architecture, and 34% said COVID-19 accelerated a digital transformation on a company-wide basis.

It’s safe to say the global crisis came as a shock to North American manufacturers — not to mention the world at large — as many were not prepared for sharp increases in demand. While the quick pivot toward automation solutions helped take the pinch out of the crisis, so too did a concurrent effort by manufacturers to look for production partners closer to home with the requisite labor force to curb delays in production cycles stemming from supply chain bottlenecks.

This is where Rittal’s three production and modification centers provide the perfect marriage of superior automation solutions and services along with a domestic network of warehouse and distribution centers to help ensure manufacturers receive the enclosure, climate control, or IT infrastructure solutions they need to maintain regular production programs. Located in Sparks, Nevada; Houston, Texas; and Urbana, Ohio, these facilities enable Rittal to provide companies with innovative automation and control manufacturing products on a nationwide scale.

Automation already in motion

Even without the impact of the pandemic, a growing number of North American manufacturers were either reviewing reshoring and automation strategies or actively executing such plans as the COVID outbreak looked to be waning. This was in large part due to evolutions in automation capabilities from Industry 4.0 and IIoT, but also due to governmental incentives designed to spark increases in domestic output.

For example, an Executive Order signed by President Joe Biden in January 2021 was created to expand and strengthen the Buy American Act in order to maximize the purchase and use of goods and supplies manufactured in the U.S. The goal was of course to stimulate job growth in skilled manufacturing for the domestic workforce, but it also jump-started investment in the right automation solutions to equip skilled manufacturing workers with the resources to compete on a global stage.

In fact, a recent article in Automation World highlighted a Thomas Industrial Survey of 746 manufacturing companies where 69% of respondents signaled a desire to bring production back to North America, with 55% indicating they are likely to also invest in automation, particularly in the areas of performance and process control.

What this means is that North American manufacturing companies are realizing (or have already come to realize) the inextricable link between automation and reshoring in making U.S. production more viable, competitive, and profitable. In addition, the jigsaw puzzle that is connecting industrial automation and reshoring provides a faster, more actionable solution to the global supply chain complications that can be exposed when one or more global dominos fall.

With Rittal as an industrial automation and IT infrastructure partner, North American manufacturers have peace of mind in knowing that their enclosure or IT solutions are engineered, assembled, and modified under a robust umbrella of state-of-the-art design and production equipment along with highly-skilled automation specialists who know and understand the challenges of today’s variant-rich manufacturing landscape.

Whether you’re a food & beverage producer in need of enclosures for your hygienic zones, a material handler looking for the right cabinets for a crowded warehouse floor, or an automotive manufacturer in need of an Edge computing infrastructure solution for the production room floor, Rittal has a solution. In fact, Rittal designs and manufactures leading industrial and IT enclosures and racks in the U.S. for use on a global stage with universal respect and acclaim.

View our on-demand webinar to learn more about how our U.S.-made products and solutions can help you unlock true efficiency, productivity, and flexibility.